Level measurement and point level detection in the ethanol storage tank

Storage tank in an ethanol plant

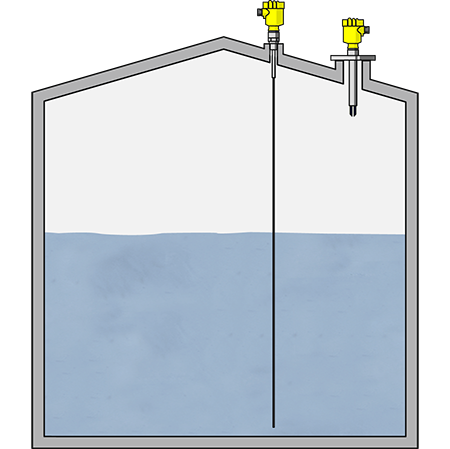

Level measurement and point level detection in the ethanol storage tank

Process data

Application

Your benefit

Recommended products

VEGAFLEX 81

Level measurement with guided radar in the bioethanol storage tanks

- High accuracy, unaffected by medium and vapours

- Simple mounting from above greatly facilitates retrofitting

- High reliability through device accreditation to SIL2/3

VEGASWING 63

Level detection with vibrating level switch as overfill protection in the bioethanol storage tanks

- Adjustment-free setup and maintenance-free operation

- Simple function test via keystroke

- Reliable point level measurement in compliance with SIL2 and WHG

Inquiry - Level measurement and point level detection in the ethanol storage tank